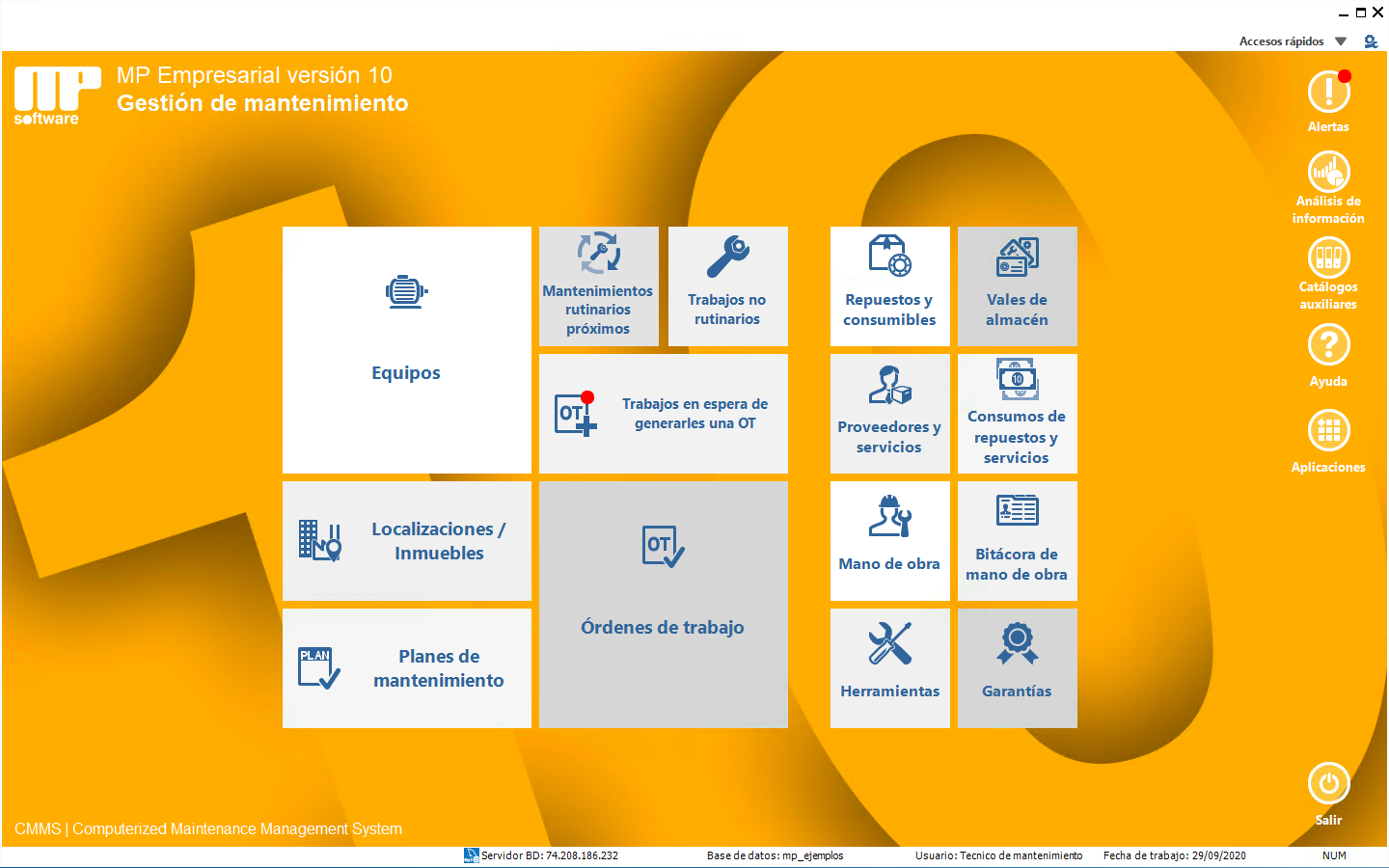

If you are a user of MP version 10we put at your disposal the complete series of video tutorials of the MPThese were made to guide you step by step in the efficient use of all its functionalities.

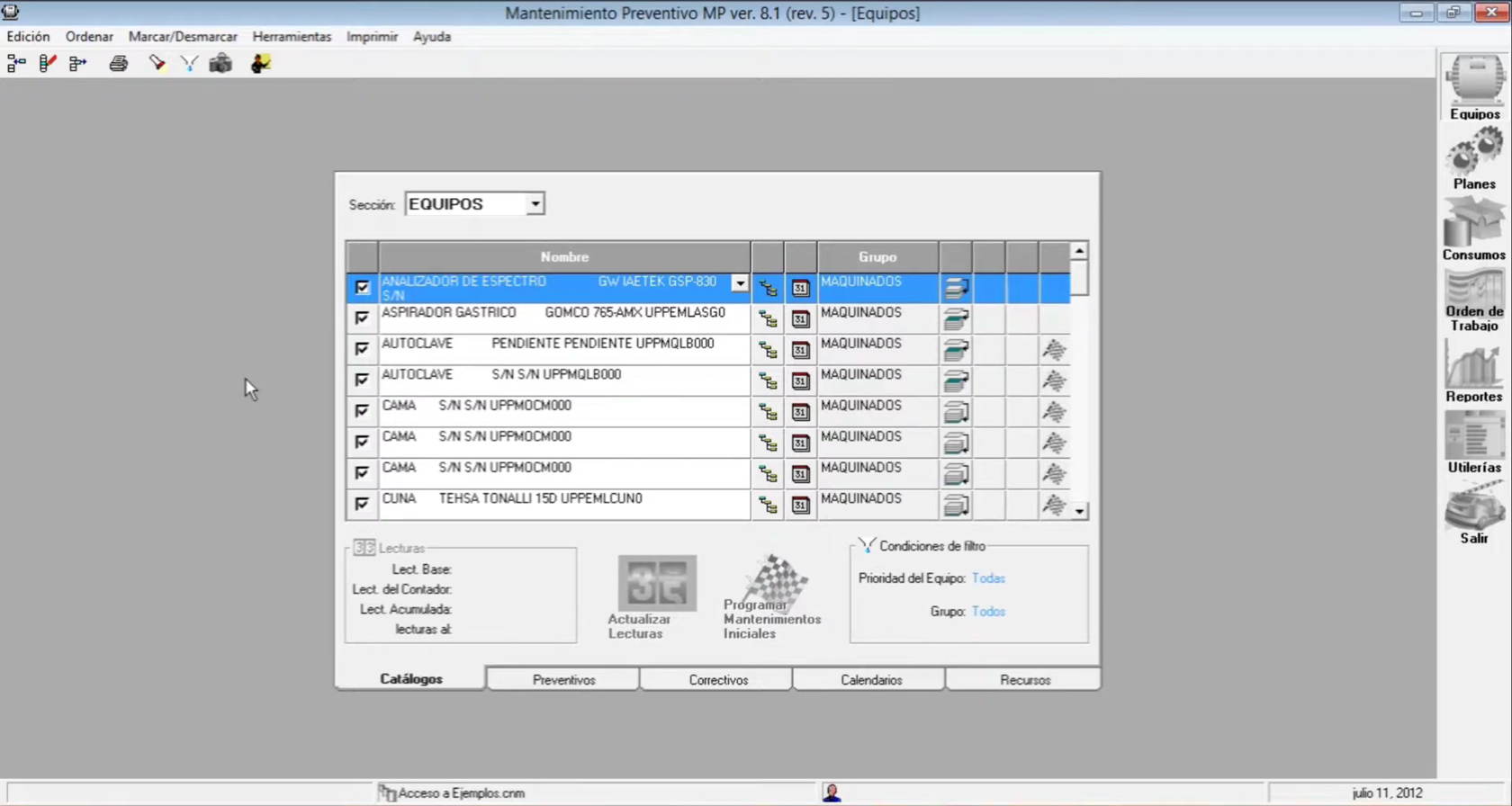

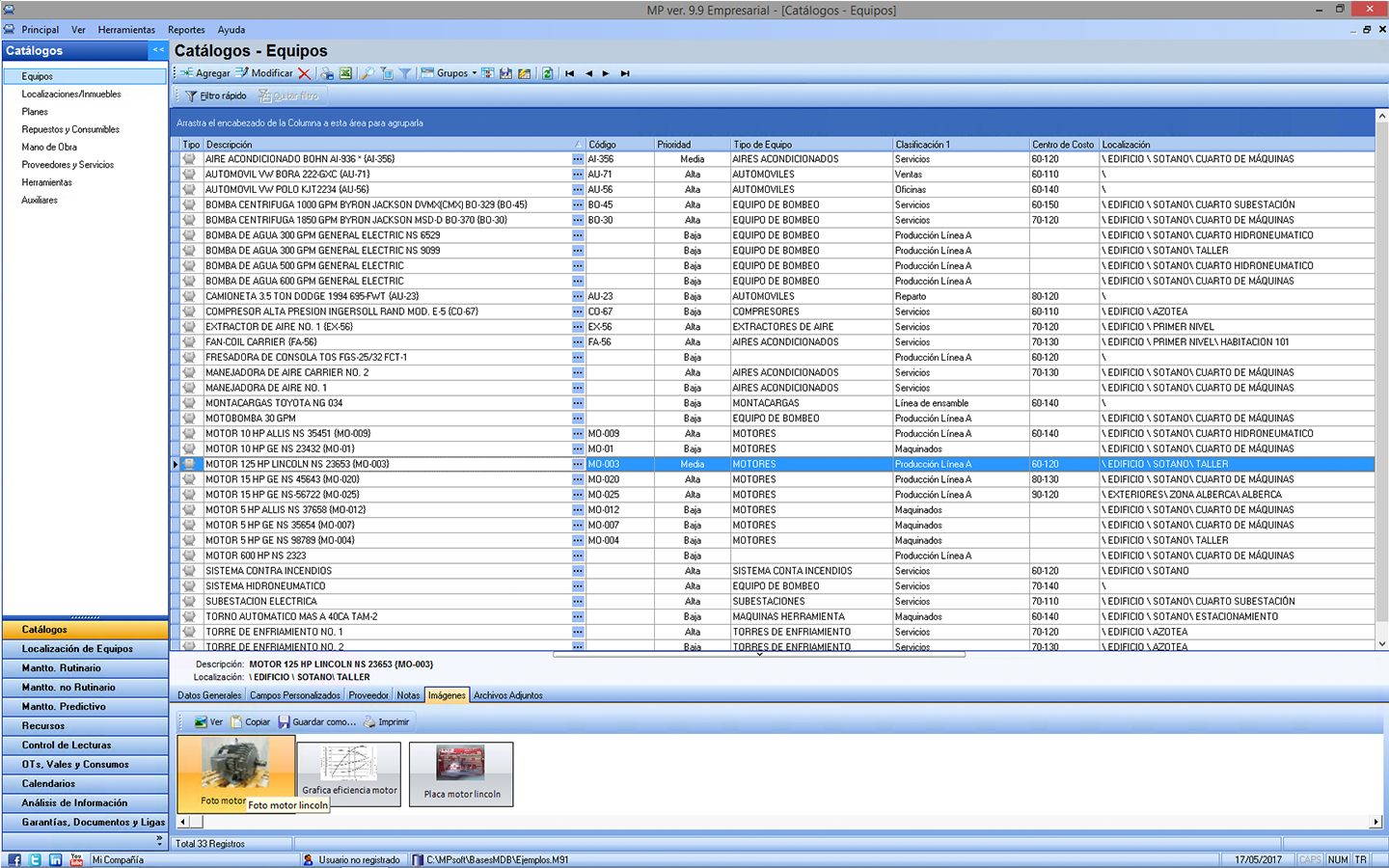

Equipment Catalog

The Equipment Catalog of MP version 10 helps you to organize and manage all the equipment in your company, allowing you to keep a detailed control of each one of them, from their acquisition to their maintenance and eventual replacement. Learn more about this and other new features in our MPindustries update.

Video - Introduction to the equipment catalog

MP version 10 allows you to document all the information about your equipment such as technical data, maintenance plans, spare parts, supplier data, images, drawings, diagrams, videos, location, warranties, etc...

Video - Multiple equipment editing

MP v.10 allows you to simultaneously edit a selection of computers helping you to make your editing work faster.

Video - Adding and editing equipment

The first step for the implementation consists of generating a catalog where the equipment whose maintenance is to be controlled is registered. Once the equipment has been registered, MP10 allows you to consult and keep all the equipment information updated.

Video - Equipment configuration options

MP 10 allows you to configure the capture fields for documenting equipment characteristics.

Video - Edit the location of a device

By assigning a location to a piece of equipment we will form a tree of locations and equipment in MPv10 that represents in a simple way the structure of our assets in the whole company.

Video - Linking equipment and locations with maintenance plans

With MP version 10, to begin scheduling routine maintenance for a piece of equipment or a location, it must first be linked to the corresponding maintenance plan.

Catalog of locations

The locations catalog of MP version 10 allows to complement the information of the equipment by relating each equipment with its respective physical location. In addition to this, the areas of the company's real estate that we register in this catalog may be linked to a preventive maintenance plan and be subject to non-routine works such as repairs and improvements reported.

Video - Introduction to the location catalog

MP v10 allows to register in a catalog the areas of the company's real estate, which in addition to being the physical location of the equipment, may be subject to maintenance.

Video - Adding and editing locations

Add the locations or properties, these will be used to assign in the MP10 a physical location to the equipment and by linking them to a plan, they will be able to receive maintenance.

Video - Consult and modify locations and equipment tree

The locations and equipment tree is a tree diagram that represents in a simple way the location of each of the equipment and real estate registered in MP version 10.

Video - Linking equipment and locations with maintenance plans

With MP version 10, to begin scheduling routine maintenance for a piece of equipment or a location, it must first be linked to the corresponding maintenance plan.

Maintenance plans

Maintenance plans or routines are models that contain the information regarding the routine maintenance activities to be performed on the equipment. Routine maintenance activities generally consist of actions focused on preventing failures and are performed in a cyclic and repetitive manner with a determined frequency.

Video - Introduction to maintenance plans

MP version 10 maintenance plans or routines are templates that contain the information regarding the routine maintenance activities to be performed on the equipment.

Video - Adding and editing maintenance plans

In MP v10, the user is the one who structures the maintenance plans for his equipment and locations based on his experience or recommendation from the equipment manufacturers.

Video - Linking equipment and locations with maintenance plans

With MP version 10, to begin scheduling routine maintenance for a piece of equipment or a location, it must first be linked to the corresponding maintenance plan.

Work orders

Work order management in a maintenance management system such as MP version 10 refers to the process of planning, assigning, executing and recording the maintenance activities necessary for the correct operation of the equipment and facilities of the implementing company.

Video - Generation of work orders

When generating work orders, the system includes the selected jobs in a work order and generates a consecutive folio number for the work order. The folio number allows you to track each work order generated.

Video - Update work orders

As the work contained in a work order is physically performed, the maintenance manager shall provide feedback in MP10 on the progress of the WO, indicating or marking the work performed.

Maintenance schedules

The maintenance schedules show in a graphical way the scheduling of maintenance work, indicating the dates on which such work should be performed. Each time the user reports on a routine work performed, the system reschedules the next date when it should be performed again, automatically adjusting the maintenance schedules.

Video - Introduction to maintenance plans and schedules

The MP10 maintenance calendar marks the days that have scheduled maintenance activities. The scheduling of maintenance work is adjusted to the configuration of your work week and non-working days, so that when maintenance work coincides with non-working days, the schedule will move the work to the next working day.

Video - Planner

Use the drag-and-drop tool to advance and postpone maintenance activities on the detailed maintenance dashboard with surprising ease. Definitely a tool that makes maintenance management easier.

Databases

All the information you enter in the PM is stored in databases and can be shared by several users at the same time.

To store, query, protect, share and manage database information, like any other computer system, requires the service of a database engine to carry out the process.

Once you decide to start the implementation you will have to create a new database with all the blank records where you will start loading your information.

Creation of a database

When you create a database, an access to the database is automatically created. The access is a file that contains encoded all the information concerning the IP or name of the server where the database is located.

Video - Simplified option

Video - Advanced option

Migration of an MP version 9 database

Migrating information from one maintenance system to another is essential to maintain business continuity, ensure data integrity and availability, optimize operational efficiency, comply with regulations, optimize resources, etc...

Video - Simplified option

Video - Advanced option

Backup of an MP version 10 database

Maintaining constant backups of your MP maintenance software database is crucial to protect your data and ensure operational continuity.

Update your maintenance software MP version 10 o MP version 9 to our new cloud platforms.

Upgrading to a SaaS (Software as a Service) scheme ensures you are in tune with the latest connectivity and Industry 4.0 trends. In addition, you will gain access to new functionalities without the need for manual upgrades, and you will benefit from free lifetime support and training to ensure successful implementation.

Take advantage of our attractive discounts when upgrading from a previous version or enjoy an extended evaluation period. You decide how you want to get started.

Offices in Mexico, Colombia, Chile, United States and International Sales.

SoftMP SA de CV| MPsoftware Colombia SAS |MPsoftware Chile SpA| CMMS Solutions Inc.

Are you aware of the new features and benefits?

MPIndustries and MPservices represent the culmination of years of experience and the addition of the functionality you've been waiting for.

Company

MP is a registered trademark of SOFTMP SA de CV.

MP is a registered trademark of SOFTMP SA de CV.

MPsoftware Official Site. All rights reserved © 2026.

![]() and MP are registered trademarks of SoftMP S.A de C.V.

and MP are registered trademarks of SoftMP S.A de C.V.